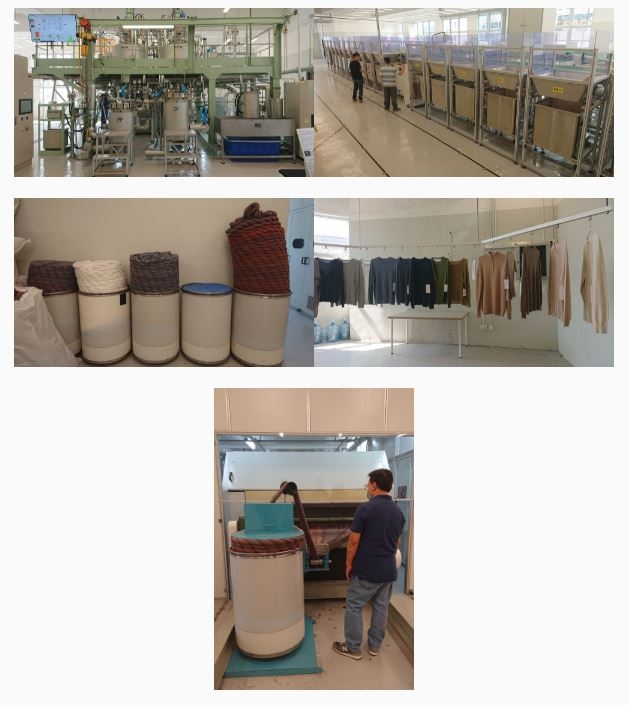

In early October 2018, CA had been invited by The Hong Kong Research Institute of Textiles and Apparel (HKRITA) to visit the Novetex Factory, located in Tai Po, to know more about new recycling techniques for handling used clothes. The new recycling techniques, “Up-cycling Post-Consumer Blends Products” and “Post-consumer Blended Textile Separation and Recycling by Hydrothermal Treatment”, use physical, chemical and biological methods to separate cotton-polyester blends and recycle post-consumer garments into fibres. The recycled fibres can then be used to reproduce textiles products such as yarn, fabric and garments. The new techniques can help retain the good quality and properties of fibres that can permit “fibre-to-fibre” recycling in order to minimize the demand for virgin materials and reduce disposal of textile waste to landfill. The used clothes have to be sorted by color initially in order to produce various colors of recycled fibres without dyeing.

Production of new clothes often causes the immense amount of pollution and resources consumption due to the large amount of water, fertilizers and pesticides usage for cotton plantation and the massive amount of toxic chemical usage in the dyeing process. The new techniques can reuse the most resources from the used clothes that can minimize the pollution and resources consumption. Thus, the new techniques are sustainable development options for the used clothes recycling industry. However, the techniques are unable to handle certain kinds of clothes such as shirts, raincoats and down. Also, the clothes being reproduced are mainly sweaters due to the limitation of the materials.

According to the waste statistics in 2016 from “Monitoring of Solid Waste in Hong Kong”, the weight of textile waste disposal was 343 tons/day and the weight of textile recycled was 4200 tons/year. As a result, the textile recycling rate was less than 3.4% in 2016. The new techniques can reproduce approx. 25 tons of recycled fibres each month at the moment. Based on this capacity, the new techniques should reproduce 300 tons recycled fibres for a year (25 tons x 12 months), which only contributes to a small percentage of a single day’s worth of textile waste disposal.

The texture of the recycled fibres and clothes are soft and the design of the recycled garments is the same as the general garments selling in boutiques. Also, the recycled clothes are sanitized twice during production. However, not many retail shops are selling recycled garments as the costs involved are not as competitive in the local market. Thus, although there are methods to reproduce recycled clothes, the demand of the recycled clothes is relatively low and it surely takes time to compete with current fast fashion trends.

Actually, the new technique is just one of the many means to handle used clothes. Technology alone cannot solve the abundant amount of textile waste in the long run. There are always other efficient ways to reduce the textile waste nevertheless, such as only buy what you need and choose eco friendly products.

Reference:

1 Environmental Protection Department (2016). Monitoring of Solid Waste in Hong Kong - Waste Statistics for 2016. Retrieved from: https://www.wastereduction.gov.hk/sites/default/files/msw2016.pdf